Production line

Thanks to highly qualified employees, P&C seeks attention to detail in every single step of the production cycle, supporting the customer from the birth of the project to its complete realization.

Search for materials and volumes

The path is then divided into continuous research and a careful study of materials and volumes, enhancing the collection with an important collaborative contribution. The transposition of ancient knowledge into a modern sensitivity allows the client's stylistic ideas to be realized with authenticity and respect for the identity of each brand.

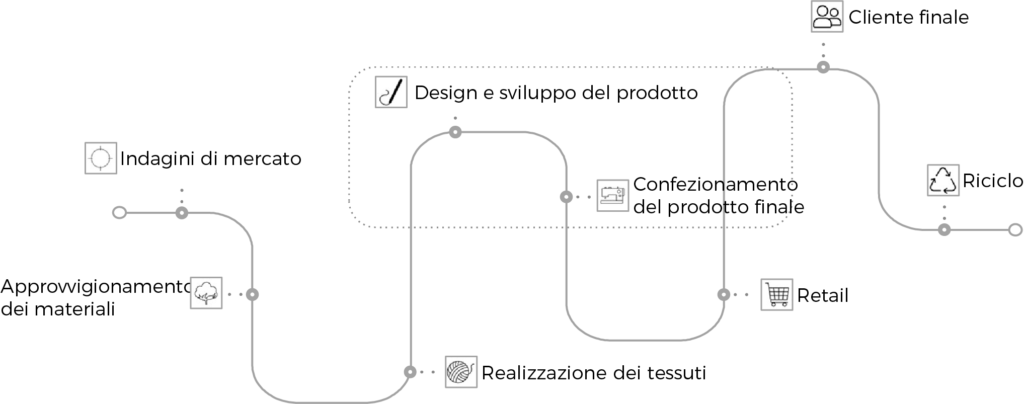

Responsabile e sostenibile

La nostra filiera

Production process

Creative process, craftsmanship.

The entire process of creating the garment begins in the product office, where we receive the first contacts with the style offices of the fashion houses. From here we get the various moodboards, through which we enter the very atmosphere of the collection. The work proceeds in the modeling shop, the place where the garment begins to come to life: together with the stylist we analyze the drawings and try to understand their characteristics in detail, in order to transform our client's ideas into reality.

The process then goes to the fabric department where, through careful research into materials, we provide our customers with refined, quality products so that they can adapt to their style needs.

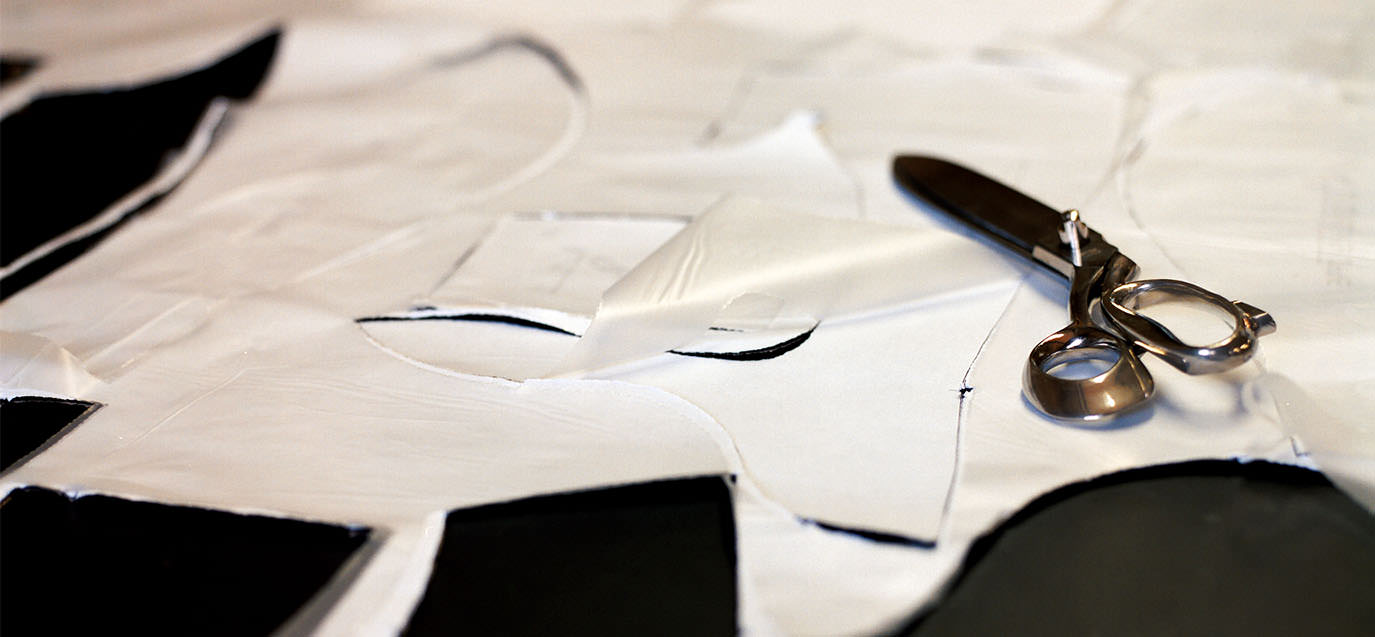

The analysis of the design and the choice of fabrics is followed by the creation of the first paper pattern, a necessary operation to understand the actual volumes of the garment. After creating the model on paper, it is transposed onto fabric: the first canvas is born, which passes into the hands of the seamstress who creates a first prototype.

Later, the fabric is tested on a mannequin to evaluate its execution and to be able to proceed with packaging.

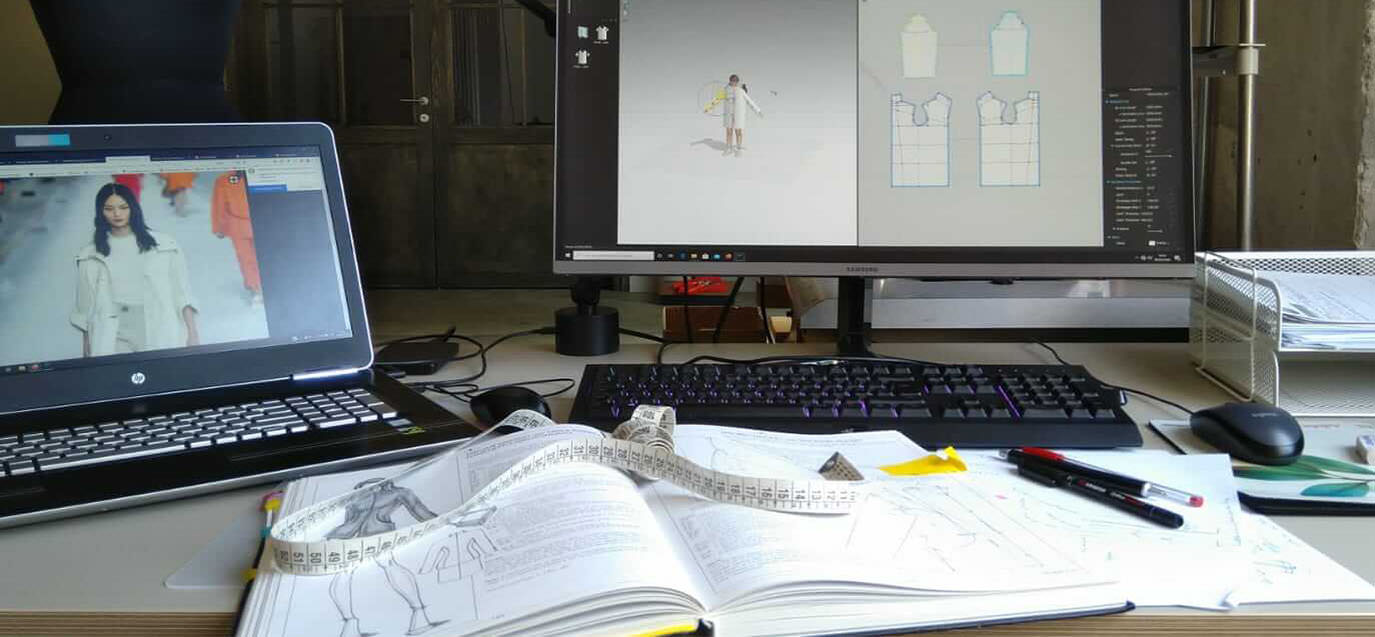

A further and definitive modification of the prototype is carried out on the computer. Subsequently, a production chart is developed that will allow the collection to be given shape.

Dopo queste fasi preliminari, realizzate su un unico modello, ha inizio la produzione vera e propria: si procede alla realizzazione del numero dei capi ordinati dal cliente. Ogni singolo modello viene confezionato mantenendo inalterata la cura per i dettagli e l’attenzione alle rifiniture riservata alla prima bozza.

Process organization takes place through production platforms, some strategically maintained internally, others strictly Made in Italy, and still others Made in Europe, all monitored in compliance with times, quality and costs.

At the end of the machine work, the garment passes back into the hands of the seamstress who gives it the final finishing touches before the final fitting on the mannequin.

Every single finished garment, according to the customer's specifications, is checked to verify that it is absolutely free of imperfections.

1.

Product department

The entire process of creating the garment begins in the product office, where we receive the first contacts with the style offices of the fashion houses. From here we get the various moodboards, through which we enter the very atmosphere of the collection. The work proceeds in the modeling shop, the place where the garment begins to come to life: together with the stylist we analyze the drawings and try to understand their characteristics in detail, in order to transform our client's ideas into reality.

2.

Choice of fabrics

The process then goes to the fabric department where, through careful research into materials, we provide our customers with refined, quality products so that they can adapt to their style needs.

3.

First prototype

The analysis of the design and the choice of fabrics is followed by the creation of the first paper pattern, a necessary operation to understand the actual volumes of the garment. After creating the model on paper, it is transposed onto fabric: the first canvas is born, which passes into the hands of the seamstress who creates a first prototype.

4.

Test on dummy

Later, the fabric is tested on a mannequin to evaluate its execution and to be able to proceed with packaging.

7.

Hand finished

At the end of the machine work, the garment passes back into the hands of the seamstress who gives it the final finishing touches before the final fitting on the mannequin.

6.

Production

8.

Last quality check

Every single finished garment, according to the customer's specifications, is checked to verify that it is absolutely free of imperfections.

1.

Product department

The entire process of creating the garment begins in the product office, where we receive the first contacts with the style offices of the fashion houses. From here we get the various moodboards, through which we enter the very atmosphere of the collection. The work proceeds in the modeling shop, the place where the garment begins to come to life: together with the stylist we analyze the drawings and try to understand their characteristics in detail, in order to transform our client's ideas into reality.

2.

Choice of fabrics

The process then goes to the fabric department where, through careful research into materials, we provide our customers with refined, quality products so that they can adapt to their style needs.

3.

First prototype

The analysis of the design and the choice of fabrics is followed by the creation of the first paper pattern, a necessary operation to understand the actual volumes of the garment. After creating the model on paper, it is transposed onto fabric: the first canvas is born, which passes into the hands of the seamstress who creates a first prototype.

4.

Test on dummy

Later, the fabric is tested on a mannequin to evaluate its execution and to be able to proceed with packaging.

4.

Production chart

A further and definitive modification of the prototype is carried out on the computer. Subsequently, a production chart is developed that will allow the collection to be given shape.

6.

Production

7.

Hand finished

At the end of the machine work, the garment passes back into the hands of the seamstress who gives it the final finishing touches before the final fitting on the mannequin.

8.

Last quality check

Every single finished garment, according to the customer's specifications, is checked to verify that it is absolutely free of imperfections.